Menowa is a plum blossom couplings supplier from china, wholesale and direct sales plum blossom couplings, jaw flex couplings, claw couplings at a reasonable price.

-

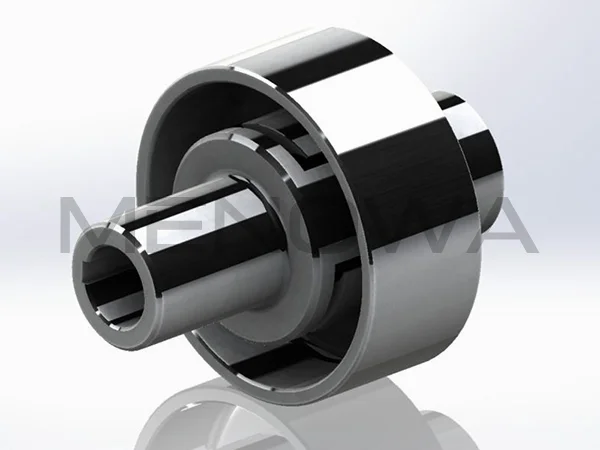

LM Plum Blossom Coupling

LM Plum Blossom Coupling -

LMD Plum Blossom Coupling

LMD Plum Blossom Coupling -

LMS Plum Blossom Coupling

LMS Plum Blossom Coupling -

LMZ-I Plum Blossom Coupling

LMZ-I Plum Blossom Coupling -

LMZ-II Plum Blossom Coupling

LMZ-II Plum Blossom Coupling -

LMPK Plum Blossom Coupling

LMPK Plum Blossom Coupling

Menowa Plum Blossom Coupling is mainly suitable for frequent starting, positive and reverse rotation, medium and high speed, medium torque and high reliability requirements of the workplace, such as: metallurgy, mining, petroleum, chemical, lifting, transportation, light industry, textile, water pump, fan and so on. Working environment temperature: -35 ℃ ~ 80℃, nominal torque 25 ~ 12500Nm, allowable speed 1500 ~ 15300r/min, high strength polyurethane elastic components wear resistance, oil resistance, large bearing capacity, long service life, safe and reliable.Menowa coupling Simple structure, small radial size, light weight, small moment of inertia, suitable for medium and high speed occasions. The coupling does not need lubrication, less maintenance work, and can run continuously for a long time.

Plum blossom coupling (also known as claw coupling) consists of two metal claw plates and an elastic body in the middle. The metal claw plate is usually made of 45 steel or aluminum alloy material, and the elastic material is mostly polyurethane or rubber material. The core principle is to transmit torque through the compression deformation of elastic bodies and compensate for axial, radial, and angular deviations. When there is a deviation between the two axes, the elastic body undergoes deformation to absorb vibration and achieve damping and buffering functions.

Core Features and Advantages

- Dynamic compensation capability

It can automatically compensate for axial displacement of 0.5-3mm, radial deviation of 1-5mm, and angular deviation of 1-5 °, adapting to shaft alignment errors under complex working conditions. - Vibration reduction performance

The elastomer can absorb 30% -50% of the vibration energy, significantly reducing the torsional stress of the transmission system, especially suitable for frequent start stop or forward reverse scenarios. - Maintenance free design

No lubrication required, polyurethane elastomer is oil resistant and insulated, with a working temperature range of -35 ℃ to+80 ℃ and a lifespan of up to 10 years. - High speed adaptability

High balance accuracy, with a permissible speed of up to 30000r/min (some models), suitable for precision drives such as servo motors and stepper motors.

Type of plum coupling

- Straight claw type: economical type, suitable for ordinary transmission, but with slight backlash.

- Curved claw type: zero gap design, suitable for high-precision scenarios such as servo motors and CNC machine tools.

- Expansion sleeve type: Keyless connection, easy disassembly, suitable for high torque servo systems.

Application field of Jaw Flex Couplings

- Precision machinery: CNC machine tool spindle, ball screw transmission.

- Heavy industry: metallurgical rolling mills, mining crushers.

- Energy equipment: pump set, fan.

The plum blossom coupling with its simple structure and reliable performance, has become a key component of modern industrial transmission. Proper selection and installation can significantly improve system efficiency and reduce maintenance costs.

In the realm of mechanical power transmission, couplings serve as critical components that connect two shafts to transmit torque while accommodating various forms of misalignment. Among the diverse range of couplings available, Plum Blossom Coupling, Jaw Flex Coupling, and Claw Coupling stand out for their versatility, reliability, and widespread application across multiple industries. These three coupling types share the core function of facilitating power transfer, yet each possesses unique structural designs, performance characteristics, and suitability for specific operating conditions.

To begin with, it is essential to understand the fundamental role of couplings in mechanical systems. Shaft misalignment is an inevitable challenge in most power transmission setups, arising from factors such as manufacturing tolerances, installation errors, thermal expansion, and structural deflection during operation. Couplings are designed to address three primary types of misalignment: angular misalignment (where the shafts intersect at an angle), parallel misalignment (where the shafts are offset parallel to each other), and axial misalignment (where the shafts move along their central axes relative to one another). Additionally, couplings may dampen vibration, reduce shock loads, and protect downstream components from damage. Plum Blossom Coupling, Jaw Flex Coupling, and Claw Coupling are all classified as flexible couplings, meaning they incorporate elastic or flexible elements to accommodate misalignment and absorb vibrations, distinguishing them from rigid couplings that offer no flexibility and require precise alignment.

Starting with Plum Blossom Coupling, this type is named for its distinctive elastic element, which resembles a plum blossom in shape. The core structure of a Plum Blossom Coupling consists of two metal hubs with evenly spaced grooves on their facing surfaces, and a flexible elastomeric insert (the plum blossom-shaped element) that fits into these grooves. The hubs are typically made from materials such as steel, aluminum alloy, or cast iron, selected based on the torque requirements and operating environment of the application. The elastomeric insert, often crafted from polyurethane, rubber, or nylon, acts as the key flexible component that enables misalignment compensation and vibration damping. The design of the grooves and the insert ensures a secure fit between the hubs and the elastic element, preventing slippage during torque transmission.

The working principle of Plum Blossom Coupling revolves around the flexibility of the elastomeric insert. When torque is applied to one hub, it is transferred through the elastic insert to the second hub, driving the connected shaft. The insert’s material properties allow it to deform slightly to accommodate angular, parallel, and axial misalignment without transferring excessive stress to the hubs or connected equipment. This deformation capacity also enables the coupling to absorb shocks and vibrations generated during operation, reducing noise and minimizing wear on bearings, gears, and other components. The plum blossom shape of the insert provides multiple contact points with the hub grooves, ensuring uniform torque distribution and enhancing the coupling’s overall stability.

One of the notable performance characteristics of Plum Blossom Coupling is its balanced combination of flexibility and torque capacity. The elastomeric insert offers sufficient flexibility to handle moderate misalignment, typically up to 1.5 degrees of angular misalignment and 0.2 to 0.5 millimeters of parallel misalignment, depending on the size and material of the insert. Axial misalignment compensation is also feasible, with ranges varying based on the coupling’s design. In terms of torque capacity, Plum Blossom Couplings are suitable for both low and medium torque applications, with smaller models handling a few Newton-meters and larger, heavy-duty versions capable of transmitting several thousand Newton-meters. The use of different elastomer materials allows for customization of performance; for example, polyurethane inserts offer higher wear resistance and load capacity compared to rubber, while nylon inserts provide better chemical resistance in certain environments.

Plum Blossom Couplings are widely used in various industries due to their versatility and cost-effectiveness. Common applications include servo motor systems, stepper motor drives, conveyor systems, pumps, fans, and light to medium-duty industrial machinery. In servo systems, where precision and responsiveness are critical, Plum Blossom Couplings are favored for their ability to transmit torque accurately while compensating for minor misalignments, ensuring smooth operation and consistent performance. Their compact design also makes them suitable for applications with limited installation space. Additionally, the easy replacement of the elastomeric insert simplifies maintenance, reducing downtime and operational costs. However, Plum Blossom Couplings have limitations in high-temperature environments, as elastomeric materials may degrade or lose flexibility when exposed to excessive heat. They are also not ideal for applications with extremely high torque or severe misalignment, as this can lead to premature failure of the insert.

Moving on to Jaw Flex Coupling, this type is another popular flexible coupling design characterized by its jaw-like hubs and elastomeric spider (or cushion) that connects them. The structure of a Jaw Flex Coupling includes two identical hubs, each featuring several protruding jaws (typically 3 to 6) arranged circumferentially. The elastomeric spider, which has corresponding recesses to match the hub jaws, fits between the two hubs, creating a secure connection. The hubs are commonly manufactured from steel, cast iron, or aluminum, while the spider is made from materials such as rubber, polyurethane, or thermoplastic elastomers. The design of the jaws and spider ensures a tight fit, preventing relative movement between the hubs and the spider during operation.

The operating principle of Jaw Flex Coupling is similar to that of Plum Blossom Coupling, relying on the elastic deformation of the spider to accommodate misalignment and transmit torque. When one hub rotates, the jaws engage with the spider, transferring torque to the opposite hub. The spider’s flexibility allows it to bend and stretch slightly, compensating for angular, parallel, and axial misalignment. This deformation also absorbs shock loads and vibrations, reducing noise and protecting the connected equipment. Unlike Plum Blossom Couplings, the jaw design provides a larger contact area between the hub and the spider, which can enhance torque transmission efficiency and stability, especially in medium-duty applications.

Jaw Flex Couplings exhibit several key performance traits that make them suitable for a wide range of applications. They offer good misalignment compensation capabilities, with angular misalignment ranges typically between 0.5 and 2 degrees, parallel misalignment up to 0.3 to 0.8 millimeters, and moderate axial misalignment capacity. The torque capacity of Jaw Flex Couplings varies significantly based on size, material, and design, with small models suitable for low-torque applications and larger, heavy-duty versions capable of handling high torque levels. The choice of spider material influences performance; rubber spiders provide excellent vibration damping but have lower wear resistance, while polyurethane spiders offer better durability and load capacity, making them suitable for more demanding operating conditions. Additionally, Jaw Flex Couplings are known for their simple installation and maintenance, as the spider can be easily replaced without disassembling the entire coupling or connected shafts.

The application range of Jaw Flex Couplings is extensive, spanning industries such as manufacturing, agriculture, automotive, and marine. They are commonly used in pumps, compressors, generators, conveyors, agricultural machinery (such as tractors and harvesters), and automotive auxiliary systems. In pump applications, Jaw Flex Couplings are valued for their ability to absorb vibrations generated by the pump’s operation, reducing stress on the motor and pump bearings. Their robustness also makes them suitable for outdoor and harsh environments, provided the appropriate materials are selected. For example, hubs made from corrosion-resistant materials and spiders with chemical resistance can be used in marine or chemical processing applications. However, like Plum Blossom Couplings, Jaw Flex Couplings have limitations in high-temperature environments, as elastomeric spiders may degrade over time. They are also not recommended for applications with extreme misalignment, as this can cause uneven wear on the spider and hubs, leading to premature failure.

Claw Coupling, often considered a variant of Jaw Flex Coupling, shares some structural similarities but has distinct design features that set it apart. The core structure of a Claw Coupling consists of two hubs with claw-shaped projections that interlock with each other, separated by a flexible element or, in some cases, operating without a separate elastomeric component (though most modern Claw Couplings incorporate a cushion for vibration damping). When an elastomeric element is used, it is typically a cylindrical or disc-shaped insert placed between the claws of the two hubs. The hubs are usually made from metal materials such as steel or aluminum, while the flexible insert (if present) is made from rubber, polyurethane, or other elastomers. The claw design allows for a compact structure, making Claw Couplings suitable for applications with limited space.

The working principle of Claw Coupling involves the interlocking claws transferring torque from one hub to the other, with the flexible insert (when used) accommodating misalignment and absorbing vibrations. In designs without a flexible insert, the coupling relies on minimal clearance between the claws to allow for slight misalignment, but this type is less common due to increased noise and wear. When a flexible insert is incorporated, the insert deforms as the hubs rotate, compensating for angular and parallel misalignment. Axial misalignment is also accommodated through the insert’s compression or expansion. The claw design provides a direct torque transfer path, ensuring efficient power transmission, while the flexible insert adds a layer of protection against shocks and vibrations.

Claw Couplings offer unique performance characteristics that make them suitable for specific applications. They are typically more compact than Plum Blossom and Jaw Flex Couplings, making them ideal for use in tight spaces where other coupling types may not fit. Their torque capacity is comparable to that of Jaw Flex Couplings, with medium-duty models capable of transmitting significant torque levels. The misalignment compensation capabilities of Claw Couplings depend on whether a flexible insert is used; models with an insert can handle angular misalignment up to 1 to 1.5 degrees and parallel misalignment up to 0.2 to 0.4 millimeters, while those without an insert have very limited misalignment capacity. The inclusion of a flexible insert also enhances vibration damping, reducing noise and wear on connected components. However, Claw Couplings with rigid claws (without an insert) are prone to higher noise levels and faster wear when misalignment is present.

Common applications of Claw Couplings include small motors, pumps, fans, household appliances, and light to medium-duty industrial machinery. They are often used in applications where compactness and cost are key considerations, such as in small-scale manufacturing equipment, medical devices, and automotive accessories. In household appliances like washing machines and dryers, Claw Couplings with flexible inserts are used to transmit torque from the motor to the drum while absorbing vibrations, ensuring quiet operation. In industrial settings, Claw Couplings are suitable for conveyor systems, small compressors, and other equipment with moderate torque requirements and limited installation space. However, their compact design can limit their torque capacity compared to larger Jaw Flex or Plum Blossom Couplings, making them less suitable for heavy-duty applications. Additionally, the claws can be prone to damage if exposed to excessive shock loads, so they are best used in applications with relatively smooth operation.

When comparing Plum Blossom Coupling, Jaw Flex Coupling, and Claw Coupling, several key differences and similarities emerge. All three are flexible couplings that use elastomeric elements to accommodate misalignment and dampen vibrations, making them suitable for applications where precise alignment is difficult to maintain. They are also relatively easy to install and maintain, with replaceable flexible elements that reduce downtime and costs. However, differences in design lead to variations in performance, torque capacity, and application suitability.

In terms of misalignment compensation, Jaw Flex Couplings generally offer the highest capacity for angular and parallel misalignment, followed by Plum Blossom Couplings, with Claw Couplings (with inserts) offering the lowest. This makes Jaw Flex Couplings the preferred choice for applications with moderate to significant misalignment, while Plum Blossom and Claw Couplings are better suited for applications with minor misalignment. Torque capacity varies by size and material, but Jaw Flex and Plum Blossom Couplings typically handle higher torque levels than Claw Couplings, making them suitable for medium to heavy-duty applications, while Claw Couplings are ideal for light to medium-duty use. Compactness is a strong suit of Claw Couplings, which are more space-efficient than the other two types, making them suitable for tight installations. Vibration damping performance is similar across all three, with the choice of elastomeric material having a greater impact than the coupling design itself.

Material selection plays a crucial role in the performance and durability of these couplings. Hubs made from steel offer high strength and torque capacity, making them suitable for heavy-duty applications, while aluminum hubs are lighter and offer better corrosion resistance, ideal for applications where weight is a concern. Cast iron hubs provide a balance of strength and cost-effectiveness, commonly used in industrial machinery. Elastomeric inserts made from polyurethane offer superior wear resistance and load capacity compared to rubber, making them suitable for demanding operating conditions, while rubber inserts provide better vibration damping and noise reduction. Nylon and thermoplastic elastomers are often used for inserts in applications requiring chemical resistance or low friction.

Installation considerations are important for ensuring the optimal performance and longevity of Plum Blossom, Jaw Flex, and Claw Couplings. Proper shaft alignment is essential, even with flexible couplings, as excessive misalignment can lead to premature wear of the elastomeric element and hubs. During installation, the shafts should be aligned as closely as possible, using alignment tools such as dial indicators or laser alignment systems. The coupling hubs should be securely fastened to the shafts using set screws, keyways, or compression fittings, ensuring no slippage occurs during operation. It is also important to select the correct coupling size based on the torque requirements, shaft diameter, and misalignment levels of the application. Using an undersized coupling can lead to overload and failure, while an oversized coupling may be unnecessarily expensive and take up excess space.

Maintenance practices for these couplings are relatively straightforward but essential for extending their service life. Regular inspection of the elastomeric element for signs of wear, cracking, or degradation is critical, as a damaged insert can compromise the coupling’s performance and lead to equipment failure. The frequency of inspection depends on the operating conditions; couplings used in harsh environments or high-vibration applications should be inspected more frequently. When the insert shows signs of wear, it should be replaced promptly to prevent further damage to the hubs and connected equipment. Additionally, the hubs should be checked for signs of corrosion, wear, or damage, and any loose fasteners should be tightened. Lubrication is generally not required for these couplings, as the elastomeric elements act as self-lubricating components, reducing maintenance requirements.

Environmental factors can significantly impact the performance and durability of Plum Blossom, Jaw Flex, and Claw Couplings. Temperature is a key consideration, as elastomeric materials have specific operating temperature ranges. Excessive heat can cause the insert to harden, crack, or lose flexibility, while extremely low temperatures can make the insert brittle and prone to failure. Couplings used in high-temperature applications should be equipped with heat-resistant elastomers, such as silicone-based materials. Humidity and moisture can lead to corrosion of metal hubs, so couplings used in wet or humid environments should be made from corrosion-resistant materials or coated with protective finishes. Chemical exposure, such as exposure to oils, solvents, or corrosive substances, can degrade elastomeric inserts and metal components, so couplings used in chemical processing or marine applications should be selected with chemical resistance in mind.

Failure modes of these couplings are typically related to wear, fatigue, or overload. The most common failure mode is the degradation of the elastomeric insert, which can occur due to age, excessive misalignment, high temperatures, or chemical exposure. Signs of insert failure include cracking, tearing, hardening, or excessive wear. Hub failure is less common but can occur due to overload, corrosion, or improper installation. For example, if the coupling is subjected to torque exceeding its capacity, the hubs may bend, crack, or shear. Improper shaft alignment can also lead to uneven wear on the hubs and insert, reducing the coupling’s service life. Regular inspection and maintenance can help identify potential issues before they lead to catastrophic failure, minimizing downtime and repair costs.

Innovations in coupling design and materials have led to improvements in the performance and versatility of Plum Blossom, Jaw Flex, and Claw Couplings. Advances in elastomer technology have resulted in the development of materials with enhanced wear resistance, temperature tolerance, and chemical resistance, expanding the range of applications for these couplings. For example, new polyurethane formulations offer better performance in high-temperature and high-vibration environments, while thermoplastic elastomers provide a balance of flexibility and durability. Additionally, improvements in manufacturing processes, such as precision machining and 3D printing, have allowed for more complex and efficient coupling designs, reducing weight and improving torque transmission efficiency. Some modern couplings also incorporate smart sensors to monitor wear and performance, providing real-time data to operators and enabling predictive maintenance.

The selection of the appropriate coupling type depends on a variety of factors, including torque requirements, misalignment levels, operating temperature, space constraints, noise considerations, and cost. For applications with moderate to significant misalignment and medium to heavy torque requirements, Jaw Flex Couplings are often the best choice. Plum Blossom Couplings are ideal for precision applications such as servo motor systems, where accurate torque transmission and minor misalignment compensation are critical. Claw Couplings are preferred for compact applications with light to medium torque requirements and minor misalignment. By carefully evaluating these factors, engineers and technicians can select the coupling that best meets the needs of their specific application, ensuring optimal performance, reliability, and longevity of the mechanical system.

In conclusion, Plum Blossom Coupling, Jaw Flex Coupling, and Claw Coupling are essential components in mechanical power transmission systems, each offering unique advantages and suitability for specific applications. Their flexible design allows for misalignment compensation and vibration damping, protecting connected equipment and ensuring smooth operation. Understanding the structural design, working principles, performance characteristics, and application ranges of these couplings is crucial for making informed selection decisions. Proper installation, regular maintenance, and consideration of environmental factors are also key to maximizing their service life and performance. As technology continues to advance, these couplings will likely see further improvements in materials and design, expanding their capabilities and applications across various industries. Whether in servo systems, pumps, conveyors, or household appliances, Plum Blossom, Jaw Flex, and Claw Couplings play a vital role in ensuring efficient and reliable power transmission, contributing to the smooth operation of countless mechanical systems worldwide.

Further research and development in the field of flexible couplings may focus on enhancing torque capacity while maintaining compactness, improving the temperature and chemical resistance of elastomeric materials, and integrating smart technologies for real-time monitoring. These advancements will enable these couplings to meet the evolving needs of industries such as renewable energy, electric vehicles, and advanced manufacturing, where high performance, reliability, and efficiency are increasingly important. As the demand for more efficient and durable mechanical systems grows, Plum Blossom, Jaw Flex, and Claw Couplings will remain integral components, continuing to play a critical role in power transmission applications for years to come.

WeChat

WeChat WhatsApp

WhatsApp