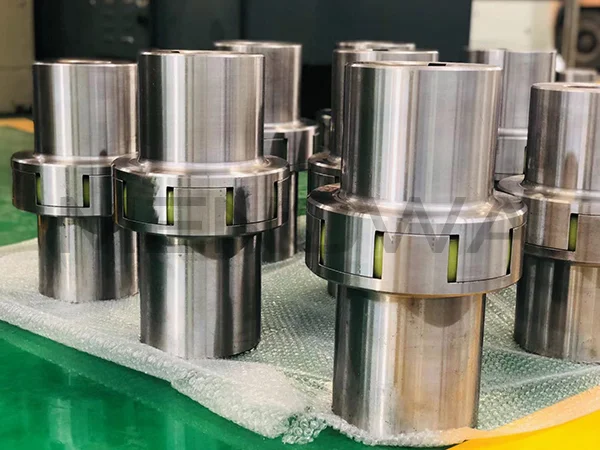

Menowa is a flexible couplings supplier from china, wholesale and direct sales flexible couplings,elastic couplings,spring couplings at a reasonable price.

Flexible Coupling refers to a coupling that has the ability to compensate for the relative displacement of the axis of the two shafts being connected, allowing for individual axial displacement of the rotor and a certain deviation in the alignment of the two connected rotors. Elastic Coupling is mainly used to connect two shafts (active shaft and passive shaft) in different mechanisms, so that they rotate together to transmit torque. Flexible couplings can be divided into two categories based on whether they contain elastic components: elastic flexible couplings and rigid flexible couplings.

In the realm of mechanical power transmission, couplings serve as critical components that connect two shafts to transmit torque while accommodating various forms of misalignment, reducing vibration, and protecting associated machinery. Among the diverse range of couplings available, Flexible Coupling, Elastic Coupling, and Spring Coupling stand out due to their unique design characteristics, functional capabilities, and adaptability to different industrial applications. While these three types of couplings share the core objective of facilitating efficient power transfer, they differ significantly in terms of structural design, material selection, operating principles, and performance attributes.

To begin with, it is essential to establish a clear understanding of each coupling type, starting with Flexible Coupling. A Flexible Coupling is a mechanical device designed to connect two rotating shafts while allowing for a certain degree of relative movement between them. This flexibility is engineered to compensate for misalignments that may occur between the shafts, which can arise from factors such as installation errors, thermal expansion, structural deformation, or operational wear. Unlike rigid couplings, which offer no flexibility and require precise alignment to function properly, Flexible Couplings can accommodate three primary types of misalignment: angular misalignment (where the shafts are not collinear and form an angle with each other), parallel misalignment (where the shafts are offset parallel to each other), and axial misalignment (where the shafts move along their respective axes). Additionally, many Flexible Couplings possess damping properties that help reduce vibration and noise generated during operation, thereby enhancing the overall stability and lifespan of the power transmission system.

The structural design of Flexible Couplings varies widely based on their intended application and the level of flexibility required. Common designs include jaw couplings, sleeve couplings with flexible elements, diaphragm couplings, and universal joints. Jaw couplings, for instance, consist of two hubs with protruding jaws that engage with a flexible elastomeric insert, often referred to as a spider. The insert acts as the flexible medium, allowing for limited misalignment and absorbing vibration. Diaphragm couplings, on the other hand, utilize thin, flexible metal diaphragms to transmit torque while accommodating misalignment. These diaphragms are typically made from high-strength alloys such as stainless steel, which enables them to withstand high temperatures and torque loads without significant deformation. Universal joints, a type of Flexible Coupling commonly used in automotive and industrial applications, consist of two yokes connected by a cross-shaped member, allowing for angular misalignment between shafts that are not in the same plane. The flexibility of these couplings is achieved through the rotational movement of the cross member within the yokes, which permits the shafts to operate at different angles while transmitting torque efficiently.

Material selection plays a crucial role in determining the performance and durability of Flexible Couplings. The hubs of these couplings are often constructed from metals such as steel, cast iron, or aluminum, which provide high strength and resistance to wear. The flexible elements, however, may be made from a variety of materials, including elastomers (rubber, polyurethane), metal alloys, or composite materials. Elastomeric elements are preferred for applications requiring vibration damping and noise reduction, as they exhibit excellent elastic properties and can absorb impact loads. Metal flexible elements, such as those used in diaphragm couplings, are suitable for high-temperature and high-torque applications where elastomers may degrade or fail. Composite materials, which combine the strength of metals with the flexibility of polymers, are increasingly being used in Flexible Couplings to achieve a balance between performance, weight, and cost.

Moving on to Elastic Coupling, this type of coupling is a subset of Flexible Couplings that relies on elastic deformation to transmit torque and accommodate misalignment. The key distinguishing feature of Elastic Couplings is the use of elastic elements, such as springs, rubber blocks, or polyurethane inserts, which deform under load and revert to their original shape when the load is removed. This elastic deformation not only allows for misalignment compensation but also provides effective vibration damping and shock absorption, making Elastic Couplings ideal for applications where smooth operation and protection of sensitive machinery are paramount.

The working principle of Elastic Couplings revolves around the transfer of torque through the elastic elements. When torque is applied to one shaft, the elastic elements deform, transferring the torque to the second shaft while absorbing any vibrations or shocks. The degree of flexibility and damping capacity is determined by the material properties, shape, and size of the elastic elements. For example, rubber-based elastic elements offer high damping capabilities but may have limited resistance to high temperatures and chemical exposure, while polyurethane elements provide better wear resistance and temperature tolerance. The design of Elastic Couplings also varies, with common configurations including tire couplings, disc couplings with elastic inserts, and torsional elastic couplings. Tire couplings, for instance, use a rubber tire as the elastic element, which provides high flexibility and damping, making them suitable for applications with significant misalignment and vibration. Torsional elastic couplings, on the other hand, are designed to absorb torsional vibrations, which occur when there are fluctuations in torque, and are often used in rotating machinery such as motors and pumps.

Elastic Couplings find widespread application in industries such as manufacturing, automotive, aerospace, and marine engineering. In manufacturing, they are used in conveyor systems, pumps, compressors, and machine tools, where they help protect equipment from damage caused by misalignment and vibration. In the automotive industry, Elastic Couplings are employed in drive shafts, transmissions, and powertrain systems to improve ride comfort and reduce noise. In aerospace applications, lightweight Elastic Couplings made from composite materials are used to transmit torque in aircraft engines and auxiliary systems, where weight reduction and reliability are critical. Marine applications also benefit from Elastic Couplings, as they can accommodate the misalignments caused by the movement of the vessel and dampen the vibrations generated by marine engines.

Spring Coupling, as the name suggests, is a type of Elastic Coupling that uses springs as the primary elastic element to transmit torque and provide flexibility. Springs offer unique advantages in terms of torsional stiffness, load capacity, and durability, making Spring Couplings suitable for applications requiring precise torque transmission and resistance to harsh operating conditions. The springs used in these couplings can be of various types, including helical springs, leaf springs, and Belleville springs, each offering distinct performance characteristics.

Helical springs are the most commonly used type in Spring Couplings due to their ability to provide linear torsional deflection and consistent torque transmission. These springs are typically made from high-carbon steel or alloy steel, which undergo heat treatment to enhance their strength and fatigue resistance. The design of Helical Spring Couplings involves wrapping the spring around a central hub or between two flanges, allowing the spring to deform torsionally when torque is applied. This torsional deformation enables the coupling to accommodate misalignment and absorb torsional vibrations, while the inherent strength of the spring ensures reliable torque transmission even under high loads. Leaf spring couplings, on the other hand, use multiple layers of thin, flexible metal strips (leaves) stacked together to form the elastic element. These couplings offer high torsional stiffness and are suitable for applications where precise alignment and minimal deflection are required. Belleville spring couplings, which use conical washers (Belleville springs) as the elastic element, provide high load capacity and excellent shock absorption, making them ideal for heavy-duty applications such as mining equipment and industrial machinery.

The performance of Spring Couplings is influenced by several factors, including the material of the springs, the number of springs, the spring rate, and the design of the coupling housing. The spring rate, which is the amount of force required to produce a unit of deflection, determines the flexibility and damping capacity of the coupling. A lower spring rate results in greater flexibility and better vibration damping, while a higher spring rate provides stiffer torque transmission and reduced deflection. The material of the springs is also critical, as it affects the coupling’s resistance to fatigue, corrosion, and high temperatures. High-carbon steel springs are cost-effective and offer good strength, but they may be susceptible to corrosion in harsh environments. Alloy steel springs, such as those made from chrome-vanadium steel, provide enhanced corrosion resistance and fatigue life, making them suitable for outdoor and marine applications. Stainless steel springs are used in applications requiring resistance to chemical exposure and high temperatures, such as food processing and pharmaceutical machinery.

One of the key advantages of Spring Couplings over other types of Elastic Couplings is their ability to maintain consistent performance over a wide range of operating conditions. Unlike elastomeric elements, which can degrade over time due to aging, temperature exposure, and chemical contact, springs are more durable and have a longer service life. Additionally, Spring Couplings can be designed to handle higher torque loads and operate at higher temperatures, making them suitable for heavy-duty and high-performance applications. However, Spring Couplings also have some limitations, including higher cost compared to elastomeric couplings, and reduced damping capacity in certain configurations. They also require more precise alignment than some other Flexible Couplings, as excessive misalignment can lead to premature wear and failure of the springs.

To better understand the differences between Flexible Coupling, Elastic Coupling, and Spring Coupling, it is important to examine their performance characteristics in terms of misalignment compensation, vibration damping, torque capacity, temperature resistance, and cost. In terms of misalignment compensation, Flexible Couplings generally offer the highest degree of flexibility, with universal joints and tire couplings capable of accommodating significant angular and parallel misalignment. Elastic Couplings, including Spring Couplings, offer moderate to high misalignment compensation, depending on the design of the elastic element. Spring Couplings with helical springs, for example, can accommodate moderate angular and parallel misalignment, while leaf spring couplings are better suited for applications with minimal misalignment.

Vibration damping is another critical performance parameter, with Elastic Couplings typically offering better damping capabilities than non-elastic Flexible Couplings. Elastomeric Elastic Couplings provide the highest level of vibration damping due to the inherent properties of rubber and polyurethane, which can absorb a large amount of vibrational energy. Spring Couplings, while offering some damping through torsional deformation of the springs, have lower damping capacity compared to elastomeric couplings. However, Spring Couplings are more effective at absorbing torsional vibrations, which are common in rotating machinery with fluctuating torque loads. Non-elastic Flexible Couplings, such as diaphragm couplings, offer minimal vibration damping but excel in high-precision applications where vibration is not a major concern.

Torque capacity varies significantly among the three coupling types, with Spring Couplings generally capable of handling higher torque loads than elastomeric Elastic Couplings. This is due to the high strength of the metal springs, which can withstand greater forces without deformation or failure. Flexible Couplings with metal elements, such as diaphragm couplings and universal joints, also offer high torque capacity, making them suitable for heavy-duty applications. Elastomeric Elastic Couplings, on the other hand, have lower torque capacity due to the limited strength of the elastic elements, which can tear or compress permanently under excessive load.

Temperature resistance is another area where the three coupling types differ. Spring Couplings and non-elastic Flexible Couplings with metal elements can operate at higher temperatures, often up to 300°C or more, depending on the material. Elastomeric Elastic Couplings, however, have limited temperature resistance, with most rubber and polyurethane elements degrading at temperatures above 100-150°C. This makes Spring Couplings and metal-based Flexible Couplings ideal for high-temperature applications such as industrial furnaces, steam turbines, and exhaust systems.

Cost is a significant consideration for many applications, with elastomeric Elastic Couplings generally being the most cost-effective option. These couplings are simple to manufacture and use low-cost materials, making them suitable for budget-conscious applications. Flexible Couplings with metal elements, such as diaphragm couplings, are moderately priced, while Spring Couplings tend to be the most expensive due to the complexity of their design and the high-quality materials required for the springs. However, the longer service life and higher performance of Spring Couplings can offset their initial cost in applications where reliability and durability are critical.

The selection of the appropriate coupling type depends on a variety of factors, including the type and magnitude of misalignment, the level of vibration and shock, torque requirements, operating temperature, environmental conditions, and cost constraints. For applications with significant misalignment and vibration, elastomeric Elastic Couplings are often the preferred choice due to their high flexibility and damping capabilities. For high-temperature and high-torque applications, Spring Couplings or metal-based Flexible Couplings are more suitable. In precision applications where minimal deflection and high accuracy are required, diaphragm couplings (a type of Flexible Coupling) are often used. It is also important to consider the compatibility of the coupling with the shafts and associated machinery, as well as the ease of installation and maintenance.

Installation and maintenance practices play a crucial role in ensuring the optimal performance and lifespan of Flexible Coupling, Elastic Coupling, and Spring Coupling. Proper installation begins with ensuring that the shafts are aligned as accurately as possible, even though Flexible and Elastic Couplings can accommodate misalignment. Excessive misalignment can lead to increased wear, reduced performance, and premature failure of the coupling and associated components. The alignment process should be performed using precision tools such as dial indicators or laser alignment systems, and adjustments should be made to minimize angular, parallel, and axial misalignment.

During installation, it is also important to ensure that the coupling is properly secured to the shafts using appropriate fasteners, such as set screws, keyways, or compression fittings. The fasteners should be tightened to the recommended torque specifications to prevent slippage and ensure reliable torque transmission. For Spring Couplings, special attention should be paid to the alignment of the springs and the housing, as improper alignment can cause uneven loading and premature wear of the springs.

Maintenance of couplings involves regular inspection, lubrication (where applicable), and replacement of worn components. Regular inspections should be conducted to check for signs of wear, damage, or deformation, such as cracks in the coupling hubs, wear on the elastic elements, or corrosion. For elastomeric Elastic Couplings, the elastic elements should be inspected for signs of aging, such as hardening, cracking, or swelling, and replaced if necessary. Spring Couplings should be inspected for broken or deformed springs, as well as wear on the spring seats and housing. Lubrication is required for some types of couplings, such as universal joints and sleeve couplings, to reduce friction and wear. The type and frequency of lubrication should follow the manufacturer’s recommendations, and contaminated or degraded lubricant should be replaced promptly.

Environmental factors can also impact the performance and lifespan of couplings. In corrosive environments, such as marine or chemical processing applications, couplings should be made from corrosion-resistant materials, such as stainless steel or coated metals. In dusty or abrasive environments, protective covers can be used to prevent debris from entering the coupling and causing wear. High-humidity environments can accelerate the degradation of elastomeric elements, so it is important to select couplings with appropriate material properties for such conditions.

Advancements in materials science and manufacturing technology have led to continuous improvements in the design and performance of Flexible Coupling, Elastic Coupling, and Spring Coupling. New composite materials, such as carbon fiber-reinforced polymers, are being used to create lightweight, high-strength couplings that offer improved performance and durability. Additive manufacturing (3D printing) technology is also being employed to produce complex coupling designs with optimized geometries, allowing for enhanced flexibility, torque capacity, and vibration damping. Additionally, the integration of sensors and monitoring systems into couplings is enabling real-time monitoring of performance parameters such as torque, vibration, and temperature, allowing for predictive maintenance and reducing the risk of unexpected failures.

In conclusion, Flexible Coupling, Elastic Coupling, and Spring Coupling are essential components in mechanical power transmission systems, each offering unique advantages and capabilities. Flexible Couplings provide versatile misalignment compensation, Elastic Couplings excel in vibration damping and shock absorption, and Spring Couplings offer high torque capacity, durability, and consistent performance in harsh operating conditions. The selection of the appropriate coupling type requires a thorough understanding of the application requirements, including misalignment, vibration, torque, temperature, and environmental factors. Proper installation, regular maintenance, and adherence to manufacturer’s recommendations are critical to ensuring the optimal performance and lifespan of these couplings. As technology continues to advance, the design and performance of these couplings will continue to improve, further enhancing their role in enabling efficient and reliable power transmission across a wide range of industries.

The importance of selecting the right coupling cannot be overstated, as it directly impacts the efficiency, reliability, and safety of the entire power transmission system. A well-chosen coupling can reduce maintenance costs, extend the lifespan of machinery, and improve overall operational performance. Conversely, an improperly selected coupling can lead to frequent breakdowns, increased downtime, and costly repairs. By understanding the characteristics, advantages, and limitations of Flexible Coupling, Elastic Coupling, and Spring Coupling, engineers and industry professionals can make informed decisions that meet the specific needs of their applications, ensuring optimal performance and long-term reliability.

Furthermore, ongoing research and development in the field of couplings are focused on addressing emerging challenges, such as the need for more energy-efficient designs, reduced environmental impact, and compatibility with advanced machinery and automation systems. As industries continue to evolve, the demand for high-performance, durable, and versatile couplings will remain strong, driving further innovations in material science, design, and manufacturing. Whether in traditional industrial applications or cutting-edge technologies, Flexible Coupling, Elastic Coupling, and Spring Coupling will continue to play a vital role in powering the world’s machinery and equipment.

WeChat

WeChat WhatsApp

WhatsApp