Menowa is a diaphragm couplings supplier from china, wholesale and direct sales flexible diaphragm couplings, membrane couplings, steel laminae couplings, shim pack couplings at a reasonable price.

-

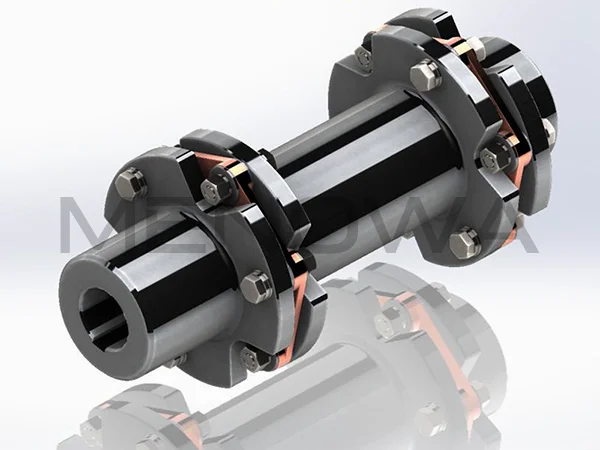

JMI Diaphragm Coupling

JMI Diaphragm Coupling -

JMII Diaphragm Coupling

JMII Diaphragm Coupling -

JMIJ Diaphragm Coupling

JMIJ Diaphragm Coupling -

JMIIJ Diaphragm Coupling

JMIIJ Diaphragm Coupling -

SJM Diaphragm Coupling

SJM Diaphragm Coupling -

DJM Diaphragm Coupling

DJM Diaphragm Coupling

Menowa Diaphragm coupling is used for torque transmission equipment, there are 7 types of structure, the smallest coupling transmission torque range from 10Nm, and the largest coupling transmission torque range of up to 8100000Nm, because the diaphragm has 6 Angle, 8 Angle or more or 10 Angle modeling, so the torque transmission is very uniform,Menowa coupling applicable ambient temperature can be from -20 ℃ to at least +280℃, the use of special materials, with high torque rigidity and high sensitivity, large torque load, zero rotation gap, with oil resistance and corrosion resistance, the ambient temperature can be from -196℃ to at least +350℃, Menowa coupling can be used in areas with explosion risk,High-speed series torque transmission range: 5000Nm to 56000Nm, diaphragm installation, easy to replace, components according to the modular principle of manufacturing, very widely used,High-speed diaphragm couplings and low-speed high-torque couplings can be widely used in general mechanical equipment, such as paper machinery, pump rotation systems, ventilation equipment, material processing, etc. The smallest coupling is available for the control system.

Flexible Diaphragm Coupling is a high-performance metal elastic element flexible coupling, which is composed of a diaphragm group composed of multiple layers of stainless steel thin plates stacked together and connected by bolts in a staggered manner between the two halves of the coupling. The core principle is to compensate for the relative displacement between two axes (axial, radial, angular) through the elastic deformation of the diaphragm, without lubrication and without rotational clearance. Typical structures are divided into:

- Single membrane type: suitable for small offset compensation (angular deviation ≤ 1.5 °).

- Double diaphragm type: By enhancing the compensation capability through two sets of diaphragms, it can simultaneously handle multi-directional deviations, and the angular compensation capability can reach twice that of traditional gear couplings.

Core Features and Advantages of Membrane Coupling

- High precision transmission

The transmission efficiency is as high as 99.86%, with zero backlash, suitable for servo systems and precision machinery (such as CNC machine tools and aviation power systems), ensuring no slip in speed transmission. - Resistant to harsh environments

Temperature range: -80 ℃ to+300 ℃, special materials can be extended to -196 ℃~+350 ℃.

Corrosion resistance: Stainless steel diaphragm is resistant to acid, alkali, oil, and corrosive media, suitable for chemical pumps, naval vessels, and other scenarios. - Maintenance free design

No wear parts, no need for lubrication, with a lifespan of tens of thousands of hours. Visual inspection can assess the condition of the membrane, with extremely low maintenance costs. - Excellent dynamic performance

The vibration and noise reduction effect is significant, which can absorb impact loads and reduce bearing loads. For example, vibration transmission can be reduced by 60% in fans and compressors.

Key design parameters of Steel Laminae Coupling

- Torque transmission capacity: 10Nm to 8100000Nm (such as JZM heavy-duty series).

- Stiffness characteristics: Static torsional stiffness of 450-3400N · m/rad, suitable for servo systems with high rigidity requirements.

- Compensation capability:

Axial displacement: ± 8mm

Radial displacement: ± 6mm

Angular deviation: ± 1.5 ° (double diaphragm type can reach ± 3 °)

Selection criteria

- The calculation of torque should include peak load (such as start stop impact).

- Shaft diameter matching: Priority should be given to selecting J1 type standard shaft holes to ensure interchangeability.

Installation specifications

- Requirement for alignment: The deviation should be controlled within 1/3 of the compensation capacity (for example, it is recommended that the angular deviation of the double diaphragm coupling be ≤ 1 °).

- Bolt installation: Adopt diagonal tightening method, torque according to the manufacturer's standard (usually 50-200N · m), and fit clearance of 0.2-0.3mm.

Common fault prevention

- Abnormal noise: Check for loose bolts or twisted diaphragms (replace if the gap exceeds 0.7mm).

- Fatigue fracture: Avoid long-term overloading and regularly inspect the surface of the diaphragm for microcracks.

Shim Pack Couplings with their comprehensive performance advantages, are gradually replacing traditional gear couplings and becoming the core components in the industrial transmission field. Proper selection and installation can extend its lifespan to over 10 years and reduce the total lifecycle cost by over 40%.

In the realm of mechanical power transmission, couplings serve as critical components that connect two shafts to transmit torque while accommodating for misalignments, reducing vibration, and protecting adjacent equipment. Among the diverse range of couplings available, flexible diaphragm coupling, membrane coupling, steel laminae coupling, and shim pack coupling stand out for their unique design features, performance capabilities, and suitability for specific industrial applications. These couplings are widely utilized across sectors such as aerospace, automotive, energy, manufacturing, and marine engineering, where reliable power transmission and operational stability are paramount.

To begin with, it is essential to understand the fundamental role of flexible couplings in mechanical systems. Unlike rigid couplings, which require precise alignment between shafts and offer no flexibility, flexible couplings are engineered to tolerate various forms of misalignment, including angular, parallel, and axial misalignments. This flexibility is crucial in real-world operations, as perfect shaft alignment is often difficult to achieve and maintain due to factors such as thermal expansion, component wear, installation errors, and structural deflection. By accommodating misalignments, flexible couplings minimize stress on shafts, bearings, and other mechanical components, thereby extending the service life of the entire system and reducing downtime. Additionally, many flexible couplings possess damping properties that help reduce vibration and noise, enhancing operational comfort and protecting sensitive equipment from damage caused by excessive vibration.

Flexible diaphragm coupling is a type of flexible coupling that uses a diaphragm or a set of diaphragms as the primary flexible element to transmit torque and accommodate misalignments. The diaphragm is typically a thin, flat, or contoured piece of metal, most commonly stainless steel, due to its high strength, corrosion resistance, and fatigue resistance. The design of the diaphragm varies depending on the application requirements, with common configurations including single diaphragm, double diaphragm, and multiple diaphragm arrangements. In a single diaphragm coupling, a single diaphragm is attached to the hubs on both sides, while double diaphragm couplings feature two diaphragms separated by a spacer. The spacer in double diaphragm couplings provides additional flexibility and helps compensate for larger axial displacements compared to single diaphragm designs.

The working principle of flexible diaphragm coupling revolves around the elastic deformation of the diaphragm. When torque is applied, the diaphragm transmits the torque from one shaft to the other through its rigid sections, while its flexible regions deform to accommodate misalignments. Unlike couplings that use elastomeric elements, flexible diaphragm couplings do not rely on friction or sliding parts, which eliminates the need for lubrication and reduces wear. This design feature makes them suitable for applications where maintenance requirements must be kept to a minimum, as well as for environments where lubricants could contaminate products or processes. The absence of sliding parts also ensures consistent performance over time, as there is no gradual degradation of friction surfaces.

One of the key performance characteristics of flexible diaphragm coupling is its high torque capacity relative to its size. The use of high-strength metal diaphragms allows these couplings to transmit large amounts of torque without excessive bulk, making them ideal for compact mechanical systems. Additionally, flexible diaphragm couplings exhibit excellent torsional stiffness, which means they minimize angular deflection under load. This is particularly important in precision applications such as machine tools, robotics, and aerospace systems, where accurate torque transmission and positional control are critical. Another advantage of flexible diaphragm couplings is their ability to operate at high speeds. The balanced design of the diaphragm and hubs reduces centrifugal forces at high rotational speeds, ensuring smooth operation and preventing excessive vibration.

Flexible diaphragm couplings are widely used in a variety of industries. In the aerospace sector, they are employed in aircraft engines, auxiliary power units (APUs), and flight control systems, where reliability, high speed, and resistance to extreme temperatures are essential. In the automotive industry, they find applications in high-performance vehicles, electric vehicles (EVs), and hybrid vehicles, where they help transmit torque from the motor to the drivetrain while accommodating misalignments caused by vehicle movement and thermal expansion. In the energy sector, flexible diaphragm couplings are used in gas turbines, steam turbines, and generators, where they handle high torque and high-speed operations while protecting expensive equipment from misalignment-induced stress. They are also common in industrial machinery such as pumps, compressors, and conveyors, where their low maintenance requirements and long service life make them a cost-effective solution.

Next, membrane coupling is a closely related type of flexible coupling that shares some similarities with flexible diaphragm coupling but differs in its structural design and flexibility characteristics. While flexible diaphragm coupling typically uses flat or slightly contoured diaphragms, membrane coupling employs a thin, flexible membrane that is often cylindrical or conical in shape. The membrane is usually made from high-quality alloy steel or stainless steel, which provides the necessary strength and flexibility to withstand repeated deformation without failure. Membrane couplings can be categorized into two main types: single membrane and double membrane couplings, with double membrane designs offering greater flexibility and misalignment capacity.

The working principle of membrane coupling is based on the elastic stretching and bending of the membrane. When torque is transmitted, the membrane undergoes controlled elastic deformation to accommodate angular, parallel, and axial misalignments between the shafts. The membrane acts as a torsional spring, absorbing vibration and shock loads while maintaining a consistent torque transmission. Unlike some other flexible couplings, membrane couplings do not have any moving parts other than the elastic deformation of the membrane, which means they require no lubrication and have minimal wear. This makes them suitable for applications in clean environments, such as food processing, pharmaceutical manufacturing, and semiconductor production, where contamination from lubricants must be avoided.

Membrane couplings offer several distinct advantages over other coupling types. One of their primary benefits is their excellent misalignment compensation capability. The flexible membrane can accommodate larger angular and axial misalignments compared to rigid couplings and some other flexible couplings, making them ideal for systems where shaft alignment is challenging to maintain. Additionally, membrane couplings exhibit low torsional backlash, which is crucial in precision positioning systems and reversible drives, where any delay or play in torque transmission can affect performance. They also have a high power-to-weight ratio, meaning they can transmit large amounts of power without being overly heavy or bulky.

Another key advantage of membrane coupling is its resistance to harsh operating conditions. The use of high-strength steel membranes ensures that these couplings can withstand extreme temperatures, ranging from cryogenic temperatures to high heat environments, without compromising performance. They are also resistant to corrosion, moisture, and chemical exposure, making them suitable for outdoor applications, marine environments, and chemical processing plants. In marine applications, for example, membrane couplings are used in ship propulsion systems, where they must withstand saltwater corrosion, high torque, and variable loads while maintaining reliable operation.

Membrane couplings are employed in a wide range of industrial applications. In the semiconductor industry, they are used in wafer handling equipment, where precision and clean operation are essential. In the food and beverage industry, they find applications in pumps, mixers, and conveyors, where their lubrication-free design prevents product contamination. In the medical equipment sector, membrane couplings are used in diagnostic machines, surgical tools, and laboratory equipment, where reliability and precision are critical. They are also used in renewable energy systems such as wind turbines, where they help transmit torque from the rotor to the generator while accommodating misalignments caused by wind-induced vibrations and structural deflection.

Steel laminae coupling, also known as laminated coupling or leaf spring coupling, is a type of flexible coupling that uses a series of thin steel laminae (or leaves) as the flexible element. The laminae are typically made from high-carbon steel, alloy steel, or stainless steel, and are stacked together in a way that allows them to flex and deform to accommodate misalignments. The laminae are attached to the input and output hubs using bolts or rivets, with the number of laminae varying depending on the torque capacity and flexibility requirements of the application. Steel laminae couplings can be designed as single-row or multi-row configurations, with multi-row designs offering higher torque capacity and greater misalignment compensation.

The working principle of steel laminae coupling involves the elastic bending of the steel laminae. When torque is applied, the laminae transmit the torque from one hub to the other, while their flexibility allows them to bend and twist to accommodate angular, parallel, and axial misalignments. The stacked design of the laminae provides a high degree of flexibility while maintaining sufficient strength to handle large torque loads. Unlike couplings that use a single flexible element, the multiple laminae in steel laminae couplings distribute the load evenly, reducing stress concentration and extending the service life of the coupling.

One of the main characteristics of steel laminae coupling is its ability to absorb vibration and shock loads. The elastic nature of the steel laminae allows them to act as a shock absorber, reducing the transmission of vibration from one part of the system to another. This is particularly beneficial in applications where there are significant shock loads or vibration, such as in construction machinery, mining equipment, and agricultural machinery. By reducing vibration, steel laminae couplings help protect other mechanical components, such as bearings, gears, and shafts, from premature wear and failure.

Steel laminae couplings also offer good torsional stiffness, which is important for applications that require accurate torque transmission and positional control. They have a simple and robust design, making them easy to manufacture and maintain. Unlike some other flexible couplings, steel laminae couplings do not require complex assembly or specialized tools for installation, which helps reduce installation time and costs. Additionally, the laminae can be easily replaced if they become worn or damaged, allowing for quick maintenance and minimal downtime.

The applications of steel laminae coupling are diverse, spanning across several industries. In the construction industry, they are used in excavators, bulldozers, and cranes, where they handle high torque and shock loads while accommodating misalignments caused by the movement of the equipment. In the mining industry, they find applications in conveyor systems, crushers, and grinders, where they must withstand harsh operating conditions and heavy loads. In the agricultural sector, steel laminae couplings are used in tractors, harvesters, and irrigation systems, where their durability and vibration absorption capabilities are essential. They are also used in industrial pumps, compressors, and fans, where their simple design and low maintenance requirements make them a practical choice.

Shim pack coupling is a unique type of flexible coupling that uses a set of shims (thin, flat pieces of material) as the primary means of adjusting misalignment and transmitting torque. The shims are typically made from steel, brass, or other high-strength materials, and are stacked between two flanges or hubs to create a flexible joint. The thickness and arrangement of the shims can be adjusted to compensate for angular and parallel misalignments, making shim pack couplings highly versatile and adaptable to a wide range of applications. Unlike other flexible couplings that rely on the elastic deformation of a single element, shim pack couplings use the relative movement of the shims to accommodate misalignments.

The working principle of shim pack coupling involves the controlled movement of the shims between the hubs. When torque is transmitted, the shims transfer the torque from one hub to the other, while the gaps between the shims allow for small amounts of angular and parallel misalignment. The shims are designed to be rigid enough to transmit torque efficiently but flexible enough to accommodate minor misalignments without causing excessive stress. In some designs, the shims are arranged in a way that allows for axial movement as well, providing additional flexibility for systems with thermal expansion or contraction.

One of the key advantages of shim pack coupling is its adjustability. By adding or removing shims, or by changing the thickness of the shims, the alignment of the coupling can be fine-tuned to meet the specific requirements of the application. This makes shim pack couplings ideal for systems where alignment may change over time due to thermal expansion, component wear, or other factors. Additionally, the adjustability of shim pack couplings allows for easy installation and alignment, reducing the time and effort required to set up the system.

Shim pack couplings also offer good torque capacity and durability. The use of high-strength shims ensures that these couplings can handle large torque loads, making them suitable for heavy-duty applications. They have a simple design with no complex moving parts, which reduces the risk of failure and minimizes maintenance requirements. Unlike couplings that use elastomeric elements, shim pack couplings are not susceptible to degradation from heat, oil, or chemicals, making them suitable for use in harsh environments where other couplings may fail.

Another benefit of shim pack coupling is its cost-effectiveness. The materials used in shim pack couplings are relatively inexpensive, and their simple design makes them easy to manufacture. Additionally, the ability to replace individual shims rather than the entire coupling reduces maintenance costs over time. Shim pack couplings are also lightweight compared to some other heavy-duty couplings, which can help reduce the overall weight of the system and improve energy efficiency.

Shim pack couplings are commonly used in a variety of industrial applications. In the automotive industry, they are used in drive shafts, transmissions, and differential systems, where their adjustability and durability are essential. In the manufacturing sector, they find applications in machine tools, robotics, and assembly lines, where precise alignment and reliable torque transmission are critical. In the energy sector, shim pack couplings are used in pumps, turbines, and generators, where they can accommodate misalignments caused by thermal expansion and heavy loads. They are also used in marine applications, such as ship propulsion systems and auxiliary equipment, where they must withstand saltwater corrosion and variable loads.

When comparing flexible diaphragm coupling, membrane coupling, steel laminae coupling, and shim pack coupling, it is important to consider their unique characteristics and suitability for specific applications. Flexible diaphragm couplings excel in high-speed, precision applications where torsional stiffness and low maintenance are required. Membrane couplings offer superior misalignment compensation and are ideal for clean environments and harsh operating conditions. Steel laminae couplings are well-suited for applications with high vibration and shock loads, thanks to their vibration absorption capabilities and robust design. Shim pack couplings stand out for their adjustability and cost-effectiveness, making them a versatile choice for a wide range of applications where alignment may change over time.

Installation and maintenance practices play a crucial role in ensuring the optimal performance and longevity of these couplings. For all four coupling types, proper installation begins with accurate shaft alignment. Even though these couplings can accommodate misalignments, excessive misalignment can lead to increased stress, vibration, and premature wear. Therefore, it is essential to use precision alignment tools, such as laser alignment systems, to ensure that the shafts are aligned within the coupling’s specified limits. During installation, it is also important to follow the manufacturer’s guidelines for torque values when tightening fasteners, as over-tightening or under-tightening can affect the coupling’s performance.

Maintenance requirements vary slightly among the four coupling types, but all benefit from regular inspection. Flexible diaphragm couplings and membrane couplings require periodic visual inspections to check for signs of diaphragm or membrane damage, such as cracks, fatigue, or corrosion. If damage is detected, the diaphragm or membrane should be replaced immediately to prevent coupling failure. Steel laminae couplings should be inspected for worn or bent laminae, as well as loose fasteners. The laminae can be replaced individually if necessary, which helps reduce maintenance costs. Shim pack couplings require inspections to ensure that the shims are in good condition and that there is no excessive wear or damage to the hubs or fasteners. The shims can be adjusted or replaced as needed to maintain proper alignment.

Lubrication is not required for flexible diaphragm coupling, membrane coupling, or steel laminae coupling, as they do not have sliding parts. This eliminates the need for regular lubrication checks and reduces maintenance time and costs. Shim pack couplings also typically do not require lubrication, although some designs may benefit from a light coating of anti-seize compound on the shims to prevent corrosion and facilitate adjustment.

Environmental factors can have a significant impact on the performance and service life of these couplings. In corrosive environments, such as marine or chemical processing applications, it is important to select couplings made from corrosion-resistant materials, such as stainless steel or alloy steel with protective coatings. High-temperature environments require couplings that can withstand thermal expansion and maintain their mechanical properties at elevated temperatures. For applications with extreme cold, materials that remain flexible and strong at low temperatures should be chosen. Additionally, couplings used in dusty or dirty environments should be inspected more frequently to remove debris that could cause wear or damage.

The design and development of these four coupling types continue to evolve in response to changing industry needs and technological advancements. One emerging trend is the use of advanced materials to improve performance. For example, the use of composite materials, such as carbon fiber-reinforced polymers, in diaphragm and membrane couplings is gaining traction. These materials offer high strength-to-weight ratios, excellent corrosion resistance, and enhanced flexibility, making them suitable for high-performance applications in aerospace and automotive industries. Additionally, advances in manufacturing technologies, such as 3D printing, are enabling the production of complex diaphragm and membrane designs that were previously difficult or impossible to manufacture, allowing for improved performance and customization.

Another trend is the integration of smart technologies into couplings to enable condition monitoring and predictive maintenance. Sensors embedded in the coupling can measure parameters such as torque, vibration, temperature, and misalignment, providing real-time data on the coupling’s performance. This data can be analyzed to detect early signs of wear or damage, allowing for proactive maintenance before a failure occurs. This not only reduces downtime but also extends the service life of the coupling and adjacent equipment. Smart couplings are particularly useful in critical applications such as power generation, aerospace, and medical equipment, where reliability is of utmost importance.

Energy efficiency is also a key driver of innovation in coupling design. Manufacturers are developing couplings with lower torsional losses to improve the overall energy efficiency of mechanical systems. This is particularly important in renewable energy applications, such as wind turbines and solar power systems, where maximizing energy output is essential. Additionally, lightweight coupling designs help reduce the energy required to operate the system, further improving efficiency.

In conclusion, flexible diaphragm coupling, membrane coupling, steel laminae coupling, and shim pack coupling are essential components in mechanical power transmission systems, each offering unique advantages and suitability for specific applications. Their ability to accommodate misalignments, reduce vibration, and transmit torque reliably makes them indispensable in a wide range of industries, from aerospace and automotive to energy and manufacturing. Proper installation, regular maintenance, and careful selection based on application requirements are critical to ensuring optimal performance and longevity. As technology advances, these couplings will continue to evolve, with new materials, designs, and smart features enhancing their capabilities and expanding their applications. By understanding the characteristics and capabilities of each coupling type, engineers and industry professionals can make informed decisions to select the most appropriate coupling for their specific needs, ensuring the reliability, efficiency, and safety of their mechanical systems.

The ongoing development of these couplings is closely tied to the evolving needs of industries worldwide. As industries move toward greater automation, precision, and sustainability, the demand for high-performance, reliable, and efficient couplings will continue to grow. Flexible diaphragm coupling and membrane coupling will remain essential in precision and high-speed applications, while steel laminae coupling will continue to be a preferred choice for heavy-duty applications with high vibration. Shim pack coupling, with its adjustability and cost-effectiveness, will maintain its position as a versatile solution for a wide range of applications. By staying abreast of the latest advancements in coupling design and technology, industries can leverage these components to improve the performance and efficiency of their mechanical systems, driving innovation and growth in the global marketplace.

Furthermore, the importance of sustainability in manufacturing and industrial operations is influencing coupling design. Manufacturers are increasingly focusing on producing couplings that are durable, recyclable, and require minimal maintenance, reducing their environmental impact. The use of eco-friendly materials and manufacturing processes is becoming more prevalent, aligning with global efforts to reduce carbon emissions and promote sustainable practices. This shift toward sustainability not only benefits the environment but also helps industries reduce costs by minimizing waste and extending the service life of their equipment.

In summary, flexible diaphragm coupling, membrane coupling, steel laminae coupling, and shim pack coupling each play a vital role in modern mechanical systems. Their unique designs and performance characteristics make them suitable for a diverse range of applications, and ongoing technological advancements continue to enhance their capabilities. By understanding the strengths and limitations of each coupling type, and by implementing proper installation and maintenance practices, industries can ensure the reliable and efficient operation of their mechanical systems for years to come. As the industrial landscape continues to evolve, these couplings will remain essential components, supporting innovation and progress across all sectors.

WeChat

WeChat WhatsApp

WhatsApp